Maintaining an unbroken cold chain is critical for small businesses handling perishable products, sensitive laboratory samples, or specialty beverages. Any disruption in the cold chain can result in compromised products, lost revenue, and damaged reputation. From artisanal cheeses and frozen desserts to probiotics, enzymes, and beverage production, temperature control is essential to ensure quality, safety, and customer satisfaction.

Despite careful planning, cold chain failures can occur. Delays in transit, inadequate packaging, or improper storage can lead to temperature fluctuations that destroy products before they reach their destination. For small businesses in Madison, WI, and surrounding areas like Sun Prairie, Fitchburg, Middleton, and Verona, reliable dry ice solutions are an effective and practical way to maintain cold chain integrity. A+ Heler’s provides beverage-grade dry ice and expert guidance to help small businesses protect their products during shipping, storage, and production.

This guide explores common causes of cold chain failures, best practices for preventing product loss, and how dry ice is a versatile tool that ensures perishable items remain safe and viable.

Understanding Cold Chain Failures

A cold chain refers to the temperature-controlled supply chain used for transporting and storing perishable goods. Any break in this chain can compromise product quality, safety, and effectiveness. Common factors that cause cold chain failures include:

- Delivery Delays: Weekend shipments, holidays, or unexpected courier issues can leave products exposed to higher temperatures for longer periods.

- Improper Packaging: Using inadequate insulation or insufficient cooling material can allow heat to penetrate and raise temperatures inside containers.

- Incorrect Handling: Staff errors, such as leaving packages in warm areas or mishandling cold packs, can reduce product viability.

- Equipment Failure: Refrigeration units, freezers, and temperature-controlled trucks may fail, exposing products to harmful temperature swings.

For small businesses that rely on cold chain reliability, even brief lapses can result in spoiled products, lost revenue, and dissatisfied customers.

The Importance of Dry Ice in Preventing Product Loss

Dry ice is solid carbon dioxide that sublimates at -78.5°C (-109.3°F), making it ideal for maintaining ultra-low temperatures during storage and transport. Unlike traditional ice, dry ice does not melt into water, so it avoids creating moisture that could damage packaging or sensitive products.

Benefits of Dry Ice for Cold Chain Protection:

- Ultra-Low Temperature Maintenance: Keeps products frozen or chilled for extended periods, reducing risk of spoilage during long shipments.

- Extended Shipping Range: Enables overnight, multi-day, or even weekend shipments without compromising product integrity.

- Moisture-Free: Avoids condensation and water damage that can occur with traditional ice packs.

- Flexible Formats: Pellets, slabs, or custom sizes can be used to match container size and shipment duration.

Small businesses in Madison and surrounding areas benefit from partnering with a local dry ice provider like A+ Heler’s, which offers beverage-grade dry ice, expert guidance, and timely delivery to keep products safe.

Common Industries and Products That Rely on Dry Ice

- Food and Beverage:

- Frozen desserts, artisanal cheeses, seafood, and specialty foods require precise temperature control to maintain freshness and prevent spoilage.

- Beverage producers use dry ice for carbonated drinks, chilled cocktails, and cold storage during events or delivery.

- Frozen desserts, artisanal cheeses, seafood, and specialty foods require precise temperature control to maintain freshness and prevent spoilage.

- Probiotics and Enzyme Products:

- These delicate cultures are highly temperature-sensitive. Even brief exposure to warmth can compromise potency and viability.

- These delicate cultures are highly temperature-sensitive. Even brief exposure to warmth can compromise potency and viability.

- Scientific and Lab Samples:

- Cell cultures, enzymes, and research samples require consistent cold storage during transport or shipping to maintain experiment integrity.

- Cell cultures, enzymes, and research samples require consistent cold storage during transport or shipping to maintain experiment integrity.

- Medical and Specialty Shipments:

- Samples sent via medical courier or clinical delivery services rely on dry ice to maintain cold chain compliance and regulatory standards.

- Samples sent via medical courier or clinical delivery services rely on dry ice to maintain cold chain compliance and regulatory standards.

Packaging Strategies to Maximize Cold Chain Reliability

Proper packaging is essential to fully leverage the benefits of dry ice. Effective packaging can prevent temperature fluctuations and extend shipping duration.

Best Practices:

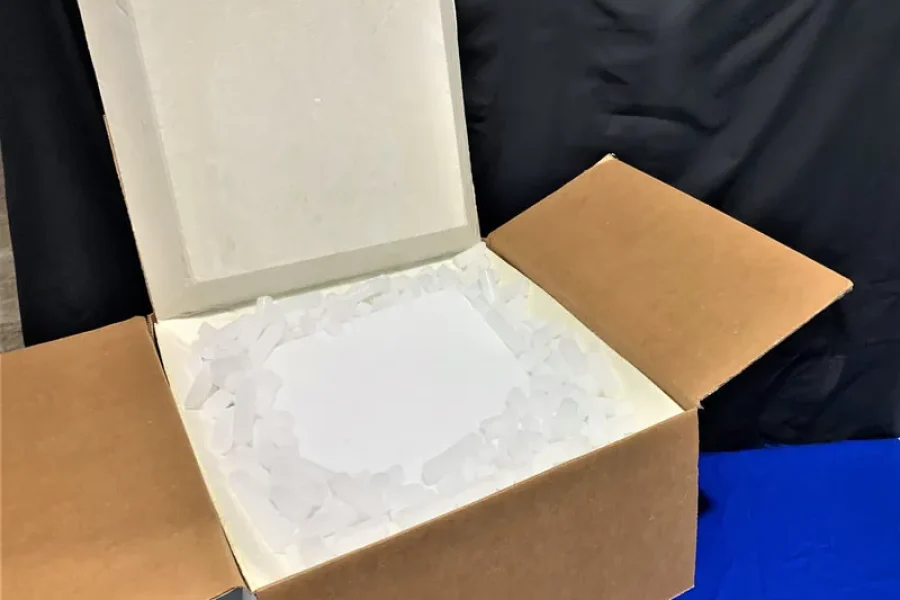

- Use High-Quality Insulated Containers: Foam-lined boxes, vacuum panels, or thermal shipping containers reduce heat transfer.

- Layer Dry Ice Strategically: Prevent direct contact with products to avoid freezing damage, and distribute dry ice evenly to maintain consistent temperatures.

- Monitor Temperature: Use data loggers or temperature indicators to track conditions during transit and quickly identify any deviations.

- Seal and Vent Containers Properly: Ensure containers are insulated and ventilated to allow sublimated CO₂ to escape safely.

Combining beverage-grade dry ice with high-quality packaging allows small businesses to confidently ship perishable products across Madison, WI, and surrounding regions without compromising quality.

Tips for Small Businesses to Prevent Cold Chain Failures

- Plan Shipments Around Peak Times: Avoid sending perishable goods right before weekends or holidays when courier schedules may be limited.

- Choose a Reliable Supplier: Partner with a local dry ice provider, like A+ Heler’s, that offers consistent quality and flexible delivery options.

- Educate Staff: Train employees in proper handling, storage, and packaging techniques for dry ice shipments.

- Monitor and Adjust: Track product temperatures during storage and transport to ensure compliance with quality standards.

- Have Backup Supplies: Maintain extra dry ice on hand to address delays or unexpected high-demand periods.

Understanding Dry Ice Formats for Optimal Cold Chain Management

Selecting the right dry ice format is essential for maximizing cold chain reliability.

- Pellets: Small, uniform pieces ideal for tight packaging, short-term shipments, or lab samples.

- Slabs/Blocks: Larger, longer-lasting dry ice pieces suitable for bulk shipments or longer transit times.

- Custom Sizes: Tailored dry ice pieces for specific container shapes or volume requirements.

Working with a knowledgeable supplier ensures that your business receives the proper dry ice format for each shipment, reducing waste and preventing temperature excursions.

Regulatory Considerations and Safety

Shipping dry ice involves regulatory considerations, especially for air transport or medical deliveries. Suppliers should provide:

- Proper labeling and documentation for DOT and IATA compliance.

- Safety instructions for handling and storage, including ventilation requirements.

- Advice on weight limits and packaging guidelines for different shipment types.

By following regulatory guidelines, small businesses can prevent shipment delays, fines, or compromised products.

Local Expertise Matters

For businesses in Madison, Sun Prairie, Fitchburg, Middleton, and Verona, local dry ice providers offer advantages that national distributors may not:

- Faster Delivery: Minimizes dry ice sublimation and ensures products stay cold longer.

- Customized Support: Suppliers can advise on packaging, quantity, and shipping methods specific to your industry.

- Emergency Solutions: Local providers can handle last-minute orders or urgent shipment needs during high-demand periods.

A+ Heler’s combines expertise, local knowledge, and beverage-grade dry ice to help small businesses maintain cold chain integrity, prevent product loss, and keep operations running smoothly.

Real-Life Benefits of Dry Ice in Cold Chain Management

- Reduced Product Loss: Prevents spoilage of perishable foods, beverages, and lab samples.

- Enhanced Customer Satisfaction: Products arrive in perfect condition, maintaining trust and brand reputation.

- Operational Efficiency: Fewer interruptions and returns allow small businesses to focus on growth.

- Cost Savings: Avoiding product loss reduces waste, saving money in the long run.

Conclusion

Cold chain failures pose a significant risk to small businesses in food, beverage, scientific research, and specialty industries. Unreliable temperature control can result in lost revenue, wasted products, and damaged reputations. Dry ice is a versatile and effective solution for preventing cold chain failures, providing ultra-low temperatures, moisture-free cooling, and flexible formats for various applications.

For businesses in Madison, WI, and surrounding areas, partnering with a trusted local dry ice supplier like A+ Heler’s ensures reliable, high-quality beverage-grade dry ice, expert guidance on handling and shipping, and responsive delivery support. By implementing proper packaging strategies, selecting the right dry ice formats, and planning shipments effectively, small businesses can maintain cold chain integrity, prevent product loss, and continue delivering high-quality goods to their customers.

Whether shipping artisanal cheeses, probiotics, enzymes, or chilled beverages, beverage-grade dry ice from a local, knowledgeable supplier ensures your products arrive safe, viable, and ready for use.